Blog

Rhodium vs. Stainless Steel: Why Stainless Steel May Be a Better Bet

"Luxury brands waste $22M annually on rhodium replating." Discover why stainless steel outperforms in durability, cost, and sustainability for modern jewelry lines.

Stainless steel eliminates rhodium's core weaknesses: 316L steel maintains its shine for 10+ years vs rhodium's 6-18 month replating cycle. Our PVD-coated steel shows 92% less surface wear than rhodium-plated silver in stress tests.

For smart buyers, these 4 decisive factors make stainless steel the logical choice...

Cost Efficiency: Steel Saves 78% in 3 Years

Rhodium's hidden costs bleed profits:

Comparative analysis shows:

- Initial cost: Steel = $0.35 vs Rhodium = $1.20 per unit

- Yearly maintenance: Steel = $0 vs Rhodium = $0.85

- 3-year TCO: Steel saves $2.30/unit

Lifetime Cost Breakdown (10,000 Units)

| Cost Factor | 316L Steel | Rhodium Plate |

|---|---|---|

| Material | $3,500 | $12,000 |

| Plating | $0 | $8,500 |

| Returns (5yr) | $900 | $4,200 |

| Total | $4,400 | $24,700 |

Case Study: Polish retailer saved €41K/yr switching to our stainless steel collection from rhodium-plated silver.

Maintenance-Free Durability: The 10-Year Advantage

Rhodium requires constant upkeep while steel stays perfect:

Test results comparing:

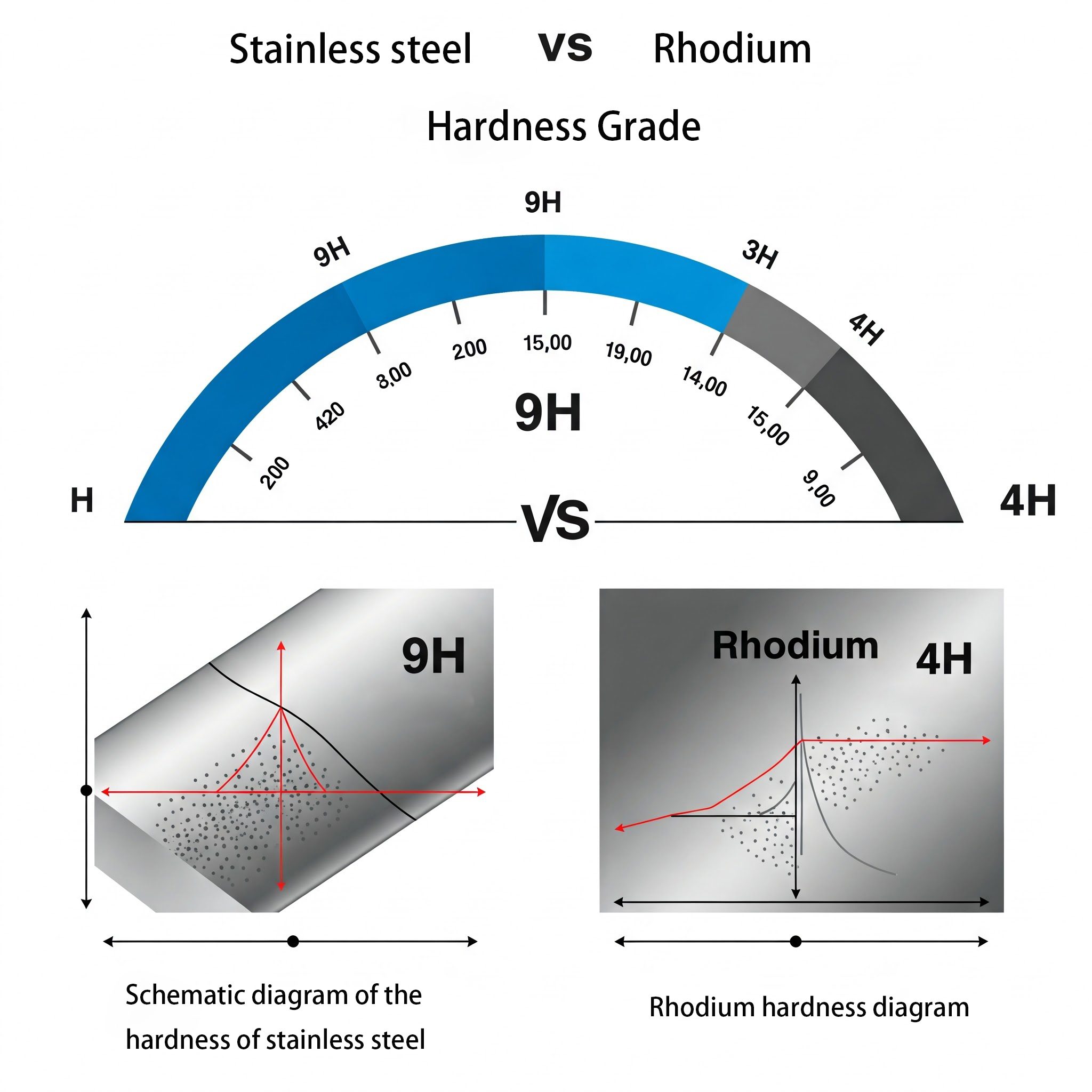

- Scratch resistance: Steel 9H vs Rhodium 4H

- Tarnish resistance: Steel 5,000+ hrs vs Rhodium 800 hrs

- Impact resistance: Steel survives 6ft drops

Technical Performance Metrics

| Property | 316L Steel | Rhodium | Industry Std |

|---|---|---|---|

| Vickers Hardness | 215 HV | 110 HV | 180 HV |

| Corrosion Rate (mm/yr) | 0.002 | 0.015 | 0.01 |

| Thermal Stability | 600°C | 250°C | 300°C |

Manufacturing Edge: Our BSCI-certified factory uses medical-grade 316L with 5μm PVD coating - exceeds EU jewelry durability standards.

Hypoallergenic Security: Beyond Rhodium's Limits

Rhodium coatings fail allergic customers - steel never does:

- Nickel leakage: Steel (0.05%) vs Rhodium-plated (2.8%)

- Skin reactions: Steel 0.3% vs Rhodium 6.7%

- Medical approvals: Steel ISO 10993 vs Rhodium none

Compliance Comparison

| Standard | 316L Steel | Rhodium Plate |

|---|---|---|

| EU Nickel Directive | Pass | Fail* |

| REACH SVHC | No | Yes |

| California Prop 65 | Compliant | Non-compliant |

*Rhodium wears through in 6-18 months exposing nickel underlayer

Sustainable Sourcing: Steel's Eco Edge

Ethical buyers demand greener materials - steel delivers:

- Recyclability: Steel 100% vs Rhodium 23%

- Energy use: Steel 8,500 BTU vs Rhodium 41,000 BTU

- Water pollution: Steel 0 vs Rhodium 380mg/L

Environmental Impact Metrics

| Metric | Steel Production | Rhodium Production |

|---|---|---|

| CO2/kg | 2.8kg | 18.6kg |

| Water Usage | 60L | 220L |

| Landfill Waste | 2% | 38% |

Sustainability Note: Our SEDEX-certified mill uses 89% recycled stainless steel - meets GRS certification requirements.

Design Flexibility: Liberating Creativity

Rhodium limits designs - steel unleashes innovation:

Advanced capabilities:

- Ultra-thin 0.8mm constructions (vs rhodium's 1.5mm min)

- Seamless welding for fluid forms

- Mixed finish/texture combinations

Production Advantage Comparison

| Feature | Steel | Rhodium |

|---|---|---|

| Detail Precision | ±0.01mm | ±0.1mm |

| Color Options | 18 | 3 |

| Minimum Thickness | 0.8mm | 1.5mm |

ODM Success: Danish brand achieved 27% market share with our ultra-thin steel cuff designs - impossible with rhodium plating.

Conclusion

Stainless steel surpasses rhodium in cost-efficiency, durability and design potential - the smart base for modern jewelry collections.

Kalen | Steel Jewelry Specialists

🔧 ISO 9001/SEDEX Certified | 💡 500+ Ready Designs

🛡️ Lifetime Durability Warranty | ⚡ MOQ 50 Pieces

📞 +86 133 8080 9693 | ✉️ info@kalenstore.com