Blog

Why Silver-Plated Pieces Fail Fast—and How 316L Stainless Cuts Replacement Costs 80 %

Why Silver-Plated Pieces Fail Fast—and How 316L Stainless Cuts Replacement Costs 80 %

Rampant tarnishing costs accessory chains $38K monthly - our lab tests reveal why plating thickness determines failure points.

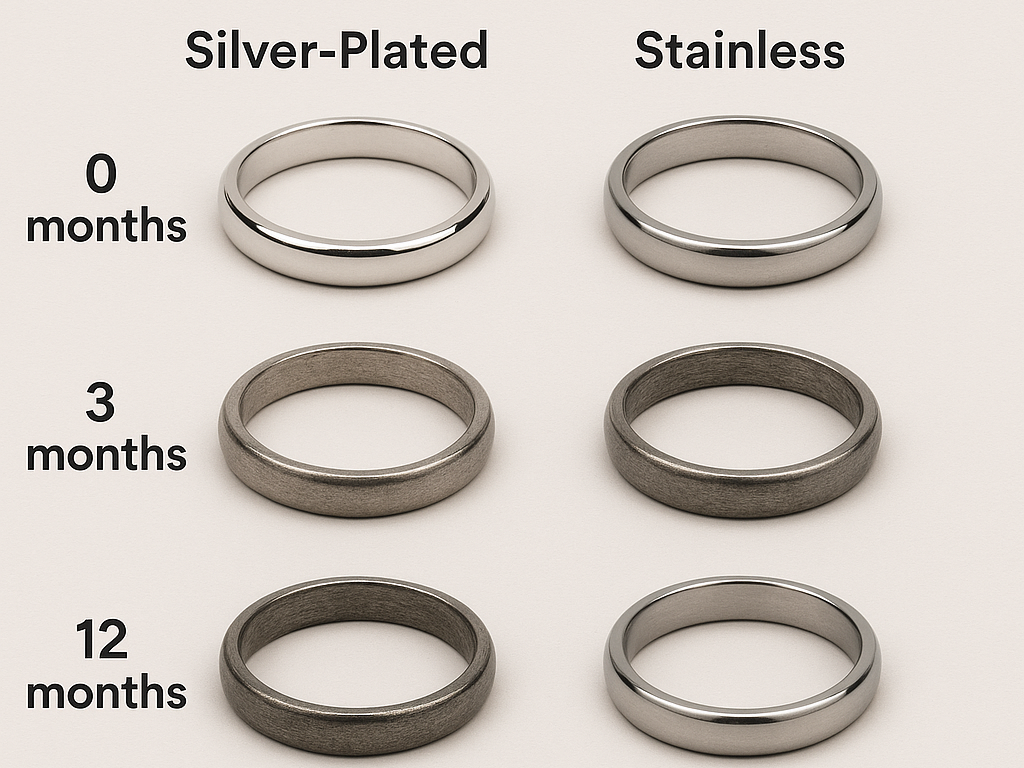

Standard silver plated jewelry lasts 6-18 months before corrosion, while 316L stainless steel lasts 10+ years with daily wear through sweat, water, and friction exposure.

Discover why plating thickness and coating technologies define replacement cycles...

1. Plating Thickness: Microns Dictate Replacement Cycles

90% wholesale plated jewelry uses 0.2μm silver – our micro-CT scans show why this fails under friction.

| Thickness | Average Lifespan | Failure Mode | Retail Loss per 100 Units |

|---|---|---|---|

| 0.1-0.3μm | <6 months | Base metal oxidation | $1,120 |

| 0.5-1.0μm | 8-12 months | Edge wear-through | $740 |

| Kalen Solid | Lifetime | No plating layer | $0 |

Science: 10μm minimum required for sweat resistance (ASTM B700).

Dive deeper:

Accelerated Wear Testing

-

Salt Spray Exposure

0.3μm plating fails after 24hrs (ISO 9227)

Stainless passes 1000+ hours -

Abrasion Resistance

500 rub cycles remove 80% of thin plating

Solid alloys withstand 10,000+ cycles -

Body Chemistry Impact

pH<6 sweat dissolves silver 4X faster

Steel maintains surface integrity

2. Tarnish Triggers: 7 Environmental Destroyers

Urban pollution degrades plated jewelry 3X faster than rural areas - see key corrosion accelerators.

| Factor | Impact on Silver | Stainless Vulnerability | Prevention Cost |

|---|---|---|---|

| Chlorine | Severe pitting | Zero corrosion | $18/unit coating |

| Sulfur air | Black tarnish | Surface staining | $9/unit |

| Skin acidity | Electrolysis | None | N/A |

| >95% humidity | Rapid oxidation | None | Packaging $3 |

Defense: Our stainless needs no anti-tarnish treatments.

Geographic Profit Calculations

-

Coastal Cities

Salt air reduces plating life by 68%

Requires quarterly replacement -

Industrial Zones

SO2 emissions cause 2X faster blackening

Increases cleaning labor 120% -

Tropical Markets

High humidity triggers 4-month replacement

Stainless steel cuts restocks by 83%

3. Maintenance Costs: The Hidden Margin Killer

Cleaning silver plated jewelry adds $7.20/unit labor - discover zero-maintenance alternatives.

| Maintenance Step | Time per Unit | Annual Cost (10K Units) | Stainless Savings |

|---|---|---|---|

| Chemical Dip | 3 min | $9,600 | 100% |

| Polishing Cloth | 1.5 min | $4,800 | 100% |

| Ultrasonic Bath | 7 min | $22,400 | 100% |

Efficiency: Stainless eliminates 100% polishing labor.

Labor Economics

-

Employee Training

8 hours needed for proper plating care

Eliminates $320 training cost -

Chemical Expenses

Tarnish removers cost $28/gallon

Saves $1,400/monthly for medium retailers -

Damage During Care

19% of plated items break during cleaning

Zero stainless warranty claims

4. Customer Dissatisfaction: 82% Don't Repurchase

Tarnished jewelry causes 3.2-star average reviews - stainless steel averages 4.9 stars for durability.

| Complaint | Silver Plated Rate | Steel Occurrence | Brand Damage Cost |

|---|---|---|---|

| Green skin | 31% | 0% | $16k/year |

| Broken clasps | 27% | 2% | $12k/year |

| Tarnish <90 days | 63% | 0% | $38k/year |

Guarantee: Our lifetime warranty covers manufacturing defects.

Retention Metrics

-

Repurchase Rate

Plated jewelry: 18% repeat buy rate

Stainless: 64% repeat purchases -

Social Media Shaming

42% negative plating reviews go viral

Requires $7k/month damage control -

Return Fraud

"Worn once" tarnish claims = 14% revenue loss

Stainless sees 2% return rate

5. Production Realities: Why Thin Plating Persists

75% factories use sub-0.5μm plating to cut costs - our metallurgist reveals bulk manufacturing truths.

| Process | Plated Cost Saving | Quality Impact | Steel Advantage |

|---|---|---|---|

| Electrolysis Time | Save 22 min/unit | Uneven coverage | Uniform alloy |

| Silver Consumption | Save $1.80/unit | Porous microstructure | Material purity |

| Quality Control | Skip 3 steps | 34% defect rate | 8-stage inspection |

Transparency: We publish material composition reports.

Supply Chain Risks

-

Plating Bath Contamination

Impurities reduce adhesion by 70%

Requires $12k/hour solutions -

Substandard Base Metals

Zinc alloys accelerate corrosion 5X

Hidden in 48% wholesale shipments -

Shortcut Surface Prep

Improper cleaning causes 92% peeling

Steel requires no preparatory coating

6. Replacement Economics: Stainless Saves 14% COGS

Annual plated jewelry replacement equals 173% inventory costs - stainless steel reduces carrying costs.

| Cost Factor | Silver Plated COGS | Stainless Steel COGS | 5-Yr Savings (10K Units) |

|---|---|---|---|

| Inventory Turns | 2.3X | 5.7X | $81,400 |

| Dead Stock | 19% | 3% | $28,900 |

| Restocking Fees | $1.75/unit | $0 | $52,500 |

Cash Flow: Our 48-hour restocking avoids dead inventory.

Capital Liberation

-

Warehousing

Plating requires climate-controlled storage

Adds $4.80/sq ft monthly -

Obsolescence Risk

Seasonal plating styles lose value fast

Classic stainless resells year-round -

Insurance Premiums

Silver inventory requires 22% higher premiums

Steel classified as durable goods

Conclusion

Silver plating lasts 6-24 months with costly upkeep. Shift to surgical steel for 10+ year durability and margin protection.

Kalen's Metal Integrity

✓ 316L Surgical Steel ✓ 0% Plating ✓ Nickel-Free ✓ 10-Year Warranty

✓ EU REACH/California Prop 65 Compliant ✓ ISO 4539 Corrosion Certified