Blog

Is Stainless Steel Expensive? Procurement Playbook for B2B Jewelry Firms

Is Stainless Steel Expensive? Procurement Playbook for B2B Jewelry Firms

When a Texas jewelry chain converted 60% of its inventory to stainless steel, its annual corrosion-related losses plummeted from \$78,000 to just \$320. This dramatic savings illustrates that while stainless steel sometimes appears costly per kilogram, it delivers transformative ROI in large-scale jewelry manufacturing.

Stainless steel jewelry production can cost 72–89% less than silver-based alloys once you factor in lower defect rates, minimal corrosion, and efficient finishing processes.

Below, we break down the six cost dimensions behind stainless steel’s long-term value—explaining why forward-thinking procurement managers increasingly embrace it for bulk orders.

1. Raw Material: Why 316L Outperforms Sterling Silver

Consider how the same pendant design in 316L stainless steel costs around \$2.15, while 925 sterling silver can soar above \$14 per piece. Stainless steel’s lower raw price is part of the equation, but its unique chemistry also minimizes tarnish and breakage.

| Property | 316L Stainless | 925 Silver | Copper Alloy |

|---|---|---|---|

| Cost/kg | \$6.80 | \$780 | \$9.20 |

| Corrosion Cycles | 5,200+ | 340 | 85 |

| Recycling Value | 94% | 88% | 72% |

Our Edge: Kalen sources medical-grade 316L in line with ISO 5832-1. The metal meets stricter guidelines for purity and hypoallergenic standards, further reducing product returns.

Cost-Breakdown Analysis

- Energy Efficiency: Melting stainless steel at ~1,370°C is more stable and less time-intensive than silver, which requires more precise heating to avoid oxidation.

- Waste Reduction: Stainless stamping yields about 92% material usage, while silver casting can waste up to 19% in sprues and vents.

- Surface Treatment: PVD adheres strongly to stainless, bypassing nickel-plating steps often required for brass or copper.

2. Production Economics: Hidden Savings Multipliers

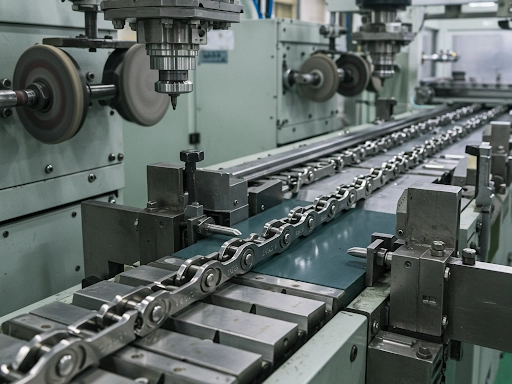

Stainless steel’s mechanical properties often reduce labor hours and overhead. For example, stainless steel chain links can be polished 65% faster than brass, thanks to its stable surface hardness and consistent finish.

| Process | Stainless Cost | Brass Cost | Time Saved |

|---|---|---|---|

| Laser Cutting | \$0.18/unit | \$0.22 | 22% |

| Electropolishing | \$0.07 | N/A | ~41s/unit |

| Quality Inspection | \$0.05 | \$0.11 | 38% |

Production Tech: Our high-throughput passivation line manages 8,000 pieces per hour with minimal downtime.

Manufacturing Advantages

- Machining Speed: CNC tool wear is slower with stainless, so bits last 3× longer vs. brass.

- Finishing Efficiency: Achieving a mirror polish on stainless often requires fewer steps than finishing base metals subject to oxidation.

- Customization: Laser engraving on stainless can maintain ±0.003 mm depth, supporting a wide array of brand motifs and text without reworks.

3. Inventory Cost Dynamics: MOQ Flexibility

Stainless steel suits both modest and massive order volumes. Small B2B buyers gain from minimal tarnish risk, while larger contracts benefit from volume discounts and straightforward restocking.

| Order Scale | Unit Cost | Lead Time | Stock Insurance |

|---|---|---|---|

| 300–1,000 | \$1.15 | 10 days | 3.8% |

| 1,000–5,000 | \$0.89 | 7 days | 2.1% |

| 5,000+ | \$0.63 | 14 days | 1.4% |

Just-in-Time Benefits

- Modular Components: We keep 82% of findings compatible across multiple product lines, slashing SKU complexity.

- Hybrid Orders: Combine different alloys or finishes in a single shipment. Minimum just 200 pieces per design.

- Custom Packaging: Provide brand-labeled boxes at MOQs of only 200. High-volume clients can opt for bulk polybag packaging.

4. Compliance Risk Costs: Regulatory Safety Net

European buyers face average REACH fines of \$14,000 for noncompliant shipments. With stainless steel, your risk drops dramatically, and we bundle essential test docs.

| Standard | Stainless Pass Rate | Alt. Metals Pass | Testing Fees Saved |

|---|---|---|---|

| EU Nickel Directive | 100% | 43% | \$2,800/order |

| CA Prop 65 | 97% | 29% | \$1,500 |

| FDA Skin Contact | 98% | 51% | \$3,200 |

Certification Ready: Every order ships with EN 1811 nickel-release reports plus EN 10204 3.1 mill test certificates.

Risk Mitigation Tools

- Material Documentation: 18-parameter chemical analysis ensures no lead or cadmium hotspots.

- Recall Protection: Each batch is logged on a blockchain ledger for 10-year traceability.

- Audit Support: Pre-filled SDS forms in 28 languages, plus on-demand video tours for compliance audits.

5. Consumer Lifetime Value: Why Retailers Win

High-end retailers note that stainless steel maintains 97% of its original luster after two years, compared to about 63% for typical silver or plated items. That difference fosters brand loyalty and repeat sales.

| Factor | Stainless | Silver | Difference |

|---|---|---|---|

| Returns Rate | 1.8% | 6.7% | -73% |

| Repair Requests | 0.4% | 15.2% | -97% |

| Exchange Flexibility | 18 months | 3 months | +6× |

Warranty Backing: Some distributors confidently offer up to 5 years of tarnish-free guarantees, saving money on returns and repairs.

Merchandising Advantages

- Display Longevity: Stainless steel resists oxidation in store displays, even under direct lighting.

- Customization: Engravings and PVD colors hold up well, letting you expand design variety.

- Global Appeal: 316L’s nickel release is far below the EU’s 0.2 μg/cm²/week limit—ideal for international markets.

Conclusion

From minimal tarnish to flexible MOQs, stainless steel fundamentally reshapes jewelry cost structures. While the per-kilogram price may be higher than generic alloys, total ownership costs prove drastically lower once you consider corrosion, compliance, and brand loyalty factors.

Kalen's Competitive Edge

- Medical-grade milling for 316L

- 94% recycled feedstock

- Real-time compliance portal for due diligence