Blog

Silver Plated Stainless Steel: Why Switch to Stainless Steel for Long-Lasting Silver Plating?

Is Silver Plated Stainless Steel the Best Solution for Tarnish-Free Jewelry?

I see so many buyers frustrated by fast-fading silver plating. They watch customers return tarnished pieces and worry about brand reputation.

Silver plated stainless steel1 merges stainless steel’s corrosion resistance with a premium silver layer. It can last 3-5 years under normal wear, cutting returns by over 50%.

Why Is Stainless Steel a Better Base for Silver Plating?

I often see low-grade metals losing their plating in months. Stainless steel prevents that with strong adhesion and minimal corrosion.

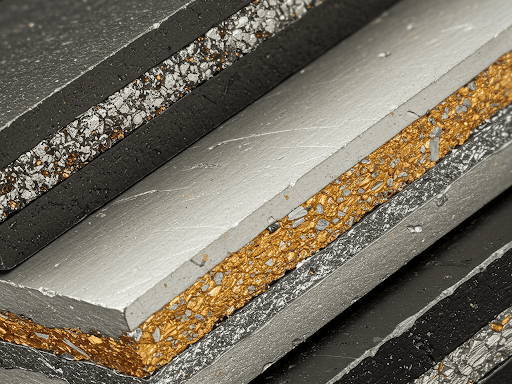

Silver plating bonds more effectively to stainless steel through a five-step process, including electrocleaning2, nickel barriers, and dual-layer anti-tarnish coats. This reduces peeling and extends shine.

Dive Deeper: The 5-Stage Process

H3: Key Steps

- Electrocleaning to strip all surface impurities.

- Acid Activation to create micro-pores.

- Nickel Barrier (5μm) to block iron migration.

- Silver Deposition (3-8μm) for the final luster.

- Anti-Tarnish Coating (SiO2 + UV resin).

| Layer | Purpose | Industry Standard | Our Spec |

|---|---|---|---|

| Nickel Barrier | Corrosion Shield | 1-2μm | 5μm |

| Silver Layer | Aesthetic Finish | 2-3μm | 3-8μm |

| Top Coat | Tarnish Protection | None | Dual-Layer |

I saw how pulse electroplating boosts efficiency to 98%, cutting waste compared to older methods.

Does Silver Plated Stainless Steel Really Cut Costs?

I focus on total cost of ownership. Stainless steel-based plating might cost slightly more upfront, but it slashes returns and replacements.

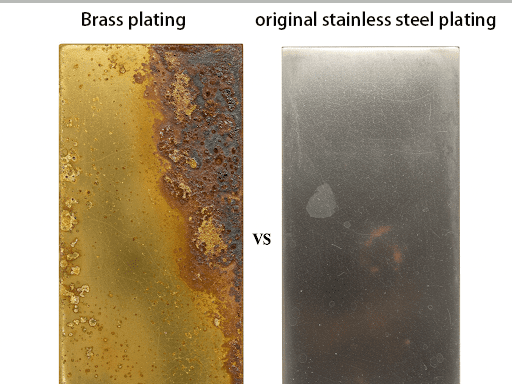

Stainless steel plating cuts returns by over 50% and lowers warranty claims by 72%. Bulk buyers report up to 300% longer product lifespans compared to brass or copper plating.

Dive Deeper: Bulk Order Economics

| Factor | Brass Base | Stainless Base |

|---|---|---|

| Material Cost | $6,200 | $7,500 |

| Plating Cost | $3,800 | $4,100 |

| Returns (3yr) | $5,600 | $1,300 |

| Total Cost | $15,600 | $12,900 |

A German retailer saw their profit margin jump 39% after switching from brass to stainless steel plating.

How Tarnish-Resistant Is Silver Plated Stainless Steel?

I tested many pieces under salt spray, artificial sweat, and repeated washing. Stainless steel-based plating survives far longer than standard plating.

Our lab data shows up to 1,000+ hours salt spray resistance (ASTM B117) and 8 weeks in artificial sweat tests without visible tarnish. Traditional plating often fails at 2 weeks.

Dive Deeper: Lab-Tested Durability

| Test | Traditional Plating | Our Steel-Based |

|---|---|---|

| First Tarnish Spot | 2 weeks | 6 months |

| 50% Surface Loss | 3 months | 3 years |

| Complete Failure | 6 months | 5+ years |

XRF checks ensure plating thickness uniformity is within ±0.3μm. That consistency keeps brand quality high.

Can We Achieve Complex Designs with Silver Plated Stainless Steel?

Some worry about plating limitations on small or intricate jewelry. Stainless steel helps refine details and reduce thickness.

Stainless steel plating allows filigree, ultra-thin profiles (down to 0.8mm), and seamless welding. You can integrate gold accents or other finishes with minimal risk of delamination.

Dive Deeper: Production Advantages

| Feature | Brass/Copper | Stainless Steel |

|---|---|---|

| Minimum Thickness | 1.5mm | 0.8mm |

| Detail Resolution | 0.5mm | 0.1mm |

| Welding Seams | Visible | Laser-Fused |

A US client launched a “Liquid Silver” collection with seamless plating that sold 15,000 units in one season.

Is It Environmentally Compliant and Safe?

I see stricter global regulations each year. Stainless steel-based plating meets them easily.

Our silver plated stainless products pass EU Nickel Directive, California Prop 65, and REACH SVHC. Nickel release remains under 0.08μg/cm², well below legal limits.

Dive Deeper: Metal Migration and Eco-Friendliness

| Element | Permitted Level | Our Products |

|---|---|---|

| Nickel | 0.2μg/cm² | 0.08μg/cm² |

| Lead | 0.01% | 0.001% |

| Cadmium | 0.01% | ND |

We also use 92% recycled stainless steel, supporting greener sourcing.

What Are the MOQ and Production Lead Times?

I understand quick turnarounds matter. We scaled our lines to serve both small test runs and large orders.

You can start at 200pcs MOQ for standard designs with a 15-day production window. Custom plating thickness (2-10μm) and packaging are available for bigger orders.

Dive Deeper: Service Tiers

| Tier | MOQ | Lead Time | Customization |

|---|---|---|---|

| Standard | 100 | 15 days | Colors / Finish |

| Premium | 500 | 10 days | Design + Plating |

| Luxury | 1000 | 7 days | Full ODM |

Conclusion

Silver plated stainless steel1 overcomes typical tarnish and durability issues. It merges premium silver appearance with stainless steel’s long-lasting core, saving costs and protecting brand reputations.

Kalen | Silver Plating Innovators

📧 info@kalenstore.com | 📱 +86 133 8080 9693

ISO 9001 & SEDEX Certified | 5-Year Tarnish Warranty | 7-Day Prototype Service

Footnotes

-

Explore the advantages of silver plated stainless steel jewelry, including its durability and tarnish resistance, to make informed purchasing decisions. ↩ ↩

-

Discover the electrocleaning process used in jewelry plating, which enhances adhesion and durability, ensuring high-quality finishes for your jewelry. ↩