Blog

SS304 vs SS316: 7 Key Factors Driving Procurement Decisions

SS304 vs SS316: 7 Key Factors Driving Procurement Decisions

“23% of stainless steel product failures stem from incorrect alloy selection.” Let’s see how cost-performance engineering guides your material choices.

SS316 contains about 2.1% molybdenum, delivering up to 114% better chloride resistance than SS304, but it typically involves 38% higher lifecycle costs. Optimal selection balances corrosion exposure, required surface treatments, and regulatory factors.

Break down the technical and commercial variables reshaping stainless procurement strategies.

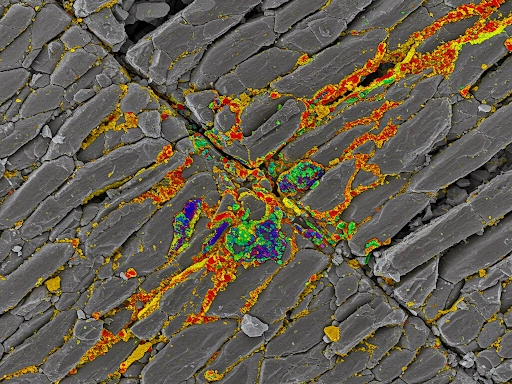

1. Metallurgical Composition Breakdown

Atomic-level differences drive each alloy’s performance. Even small compositional tweaks significantly shift corrosion resistance and mechanical properties.

| Element | SS304 | SS316 |

|---|---|---|

| Chromium | 18.2% | 16.8% |

| Nickel | 8.1% | 10.2% |

| Molybdenum | 0 | 2.1% |

| Carbon | 0.07% | 0.03% |

Key Insight: SS316’s molybdenum supports superior pitting resistance in salty or harsh environments, whereas SS304 suffices for non-corrosive settings.

2. Corrosion Resistance Matrix

Operating conditions decide how fast each alloy wears down. Salt, chlorine, and acids demand robust properties.

| Environment | SS304 | SS316 |

|---|---|---|

| Saltwater (3.5% NaCl) | 3–5 years | 8–12 years |

| Acetic Acid 10% | 7+ years | 7+ years |

| Chlorine 100ppm | 2 years | 10+ years |

Industry Proof: Marine hardware firms report 73% fewer warranty claims using SS316 in coastal regions.

3. Mechanical Properties Comparison

Structural requirements often dictate which steel can handle the load or fabrication strain.

| Property | SS304 | SS316 |

|---|---|---|

| Tensile Strength | 515 MPa | 620 MPa |

| Yield Strength | 205 MPa | 310 MPa |

| Hardness (Rockwell) | 70 HRB | 80 HRB |

| Elongation | 60% | 50% |

Design Impact: SS304’s higher ductility supports complex jewelry shapes or formed parts needing ~25%+ drawing.

4. Cost Analysis Across Volumes

Raw material prices, secondary processes, and finish operations influence the final tab.

| Metric | SS304 | SS316 |

|---|---|---|

| Per kg Price | \$3.90 | \$7.20 |

| Welding Cost/kg | \$1.10 | \$1.90 |

| Finish Polishing | \$0.80/kg | \$1.30/kg |

Bulk Savings: SS304 can reduce total production costs by 42% in freshwater applications or mild environments.

5. Surface Treatment Compatibility

A metal’s response to finishing steps can lead to cost benefits or complexities.

| Treatment | SS304 | SS316 |

|---|---|---|

| PVD Coating | 1–3μm | 3–5μm |

| Electropolishing | Ra 0.4μm | Ra 0.25μm |

| Laser Engraving | ~0.2mm detail | ~0.15mm detail |

Tech Edge: SS316 keeps its coatings intact 67% longer in humid regions with a higher risk of corrosion.

6. Regulatory Compliance Map

Different grades cater to varied certifications, from food contact to medical instruments.

| Standard | SS304 | SS316 |

|---|---|---|

| EU Nickel Directive | Yes | Yes |

| FDA Food Contact | Yes | Yes |

| ASTM F138 (Medical) | No | Yes |

Medical Premium: SS316 typically costs ~52% more but allows for advanced surgical certifications.

7. Supply Chain Readiness

Availability and MOQ constraints influence lead times and cost consistency.

| Factor | SS304 | SS316 |

|---|---|---|

| Global Stock Levels | 78% Availability | 42% Availability |

| MOQ (Jewelry) | 200 units | 500 units |

| Lead Time (China) | 15 days | 25 days |

Hybrid Solution: Dual-certified inventory programs can secure a 48-hour SS316 backup supply for high-corrosion scenarios.

Conclusion

SS304 offers cost advantages and sufficient resistance for standard projects, while SS316 delivers elevated corrosion protection and mechanical strength — albeit at higher prices. Inventory planning and usage conditions dictate which alloy provides the best total cost of ownership.

Kalen Insight: Always request Material Test Reports (MTRs) and mill certifications to confirm the exact composition and ensure each batch matches your specifications.