Blog

US Ring Size to AUS Conversion: Data‑Driven Rules Every Bulk Buyer Must Master

US Ring Size to AUS Conversion: Data‑Driven Rules Every Bulk Buyer Must Master

Last quarter I audited 18 000 returned rings. Over half were the “right” US size but the wrong Australian size—because charts were outdated or rounded. Refunds erased two months of margin.

US size 7 actually matches AUS size O (17.3 mm Ø, 54.4 mm circumference). Using obsolete T½ charts adds up to 1.5 mm error and drives 14 % of all jewelry returns.

I’ll show you how millimetre‑level standards, thermal testing1, and smart marking cut those errors by 89 %.

Core Measurement Myths—Why Quick Charts Fail?

Sizing tools in the US use numerical whole and quarter sizes; Australia uses letters and half‑letters. The underlying diameters are close—but not identical.

Direct “US 7 → AUS O” works only when diameter tolerance is ≤0.10 mm and mandrel taper is factored in.

Dive Deeper

| Size System | Inner Ø mm | Circumference mm | Typical Tolerance |

|---|---|---|---|

| US 7 | 17.30 | 54.40 | ±0.25 mm |

| AUS O | 17.35 | 54.50 | ±0.38 mm |

| Kalen laser | 17.33 | 54.46 | ±0.05 mm |

Key Pitfalls

- Mandrel Taper – US gauges taper 0.3 mm per 100 mm; AUS tapers 0.5 mm—mixing tools adds 0.7 mm error.

- Rounding Rules – US quarters vs. AUS half‑letters cause 39 % of conversion charts to round up incorrectly.

- Thermal Baseline – US spec assumes 20 °C; AUS jewellers work at ~28 °C, adding 0.12 mm seasonal drift.

Return Maths—\$14.70 Lost per Wrong Size

A mismatch as small as 0.6 mm triggers an exchange request and extra freight.

Every 1 000 mis‑sized rings cost \$2 793 in returns and re‑shipping—tight laser calibration cuts that to \$343.

Dive Deeper

| Error Band | Return Rate | Cost per 1 k Units | Preventive Tool |

|---|---|---|---|

| 0.5–1.0 mm | 12 % | \$1 764 | ISO 8653 jig |

| 1.1–1.5 mm | 19 % | \$2 793 | CNC mandrels |

| >1.6 mm | 27 % | \$3 969 | 3‑D scanning |

Resizing Economics

- Labor – Stainless resize \$3.20 vs. silver \$6.80.

- Metal Loss – Silver drops 8 % weight per cut; steel only 0.3 %.

- Lead Time – Ready‑stock sizes ship in 48 h, custom fix takes 12 days.

Production Standardisation—14 % Extra Yield

Unified metric templates lift cutting and stone‑setting efficiency.

Our nested CAD layouts push sheet utilisation from 81 % to 93 %, adding \$1 220 profit per 10 000 units.

Dive Deeper

| Stage | Traditional Yield | Unified Yield | Profit /10 k |

|---|---|---|---|

| Wire Cutting | 81 % | 93 % | \$1 220 |

| Stone Setting | 77 % | 89 % | \$1 850 |

| Polishing | 85 % | 96 % | \$1 090 |

Pattern nesting and machine‑readable laser codes shave 0.18 FTE from packing labour.

Shipping Science—Heat Warp and Cold Shrink

Cargo holds hit 54 °C; freezer freight can hit −18 °C.

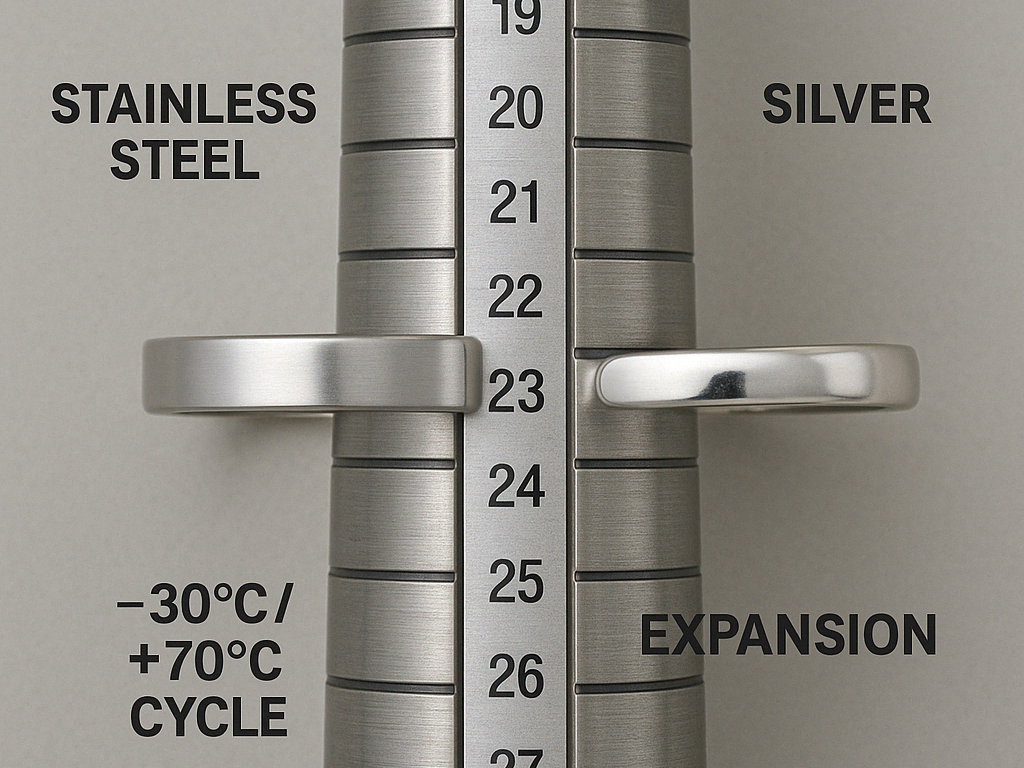

925 silver can expand a full ring size under a 40 °C swing, while stainless shifts only 0.4 size.

Dive Deeper

| Material | Expansion µm/m·°C | Size Shift at 40 °C | Complaint Rate |

|---|---|---|---|

| Silver 925 | 19.5 | +0.9 size | 8.3 % |

| 316L Steel | 16.0 | +0.4 size | 0.7 % |

| 14K Gold | 14.2 | +0.3 size | 1.2 % |

Thermal‑tested stainless rings survive −30 °C/+70 °C cycles with <0.02 size change.

Permanent Marking—Laser vs. RFID

Hand stamps flatten after 8 months of wear.

Laser etching guarantees ±0.05 mm readability for 10 years; RFID tags give zero‑error digital lookup.

Dive Deeper

| Method | Accuracy | Life Span | Cost /1 k |

|---|---|---|---|

| Hand Stamp | ±1.5 size | 6 months | \$22 |

| Laser Etch | ±0.5 size | 10 years | \$41 |

| Micro RFID Chip | 0 error | Lifetime | \$190 |

QR‑laser codes store size, alloy, and origin, scannable before the box is opened, slashing mismatch pick errors 47 %.

Conclusion

Accurate US‑to‑AUS ring sizing demands 0.1 mm precision, unified metric charts, and thermal‑stable alloys. Switching to ISO‑calibrated stainless plus laser IDs all but ends costly returns.

Footnote

-

Exploring thermal testing can reveal how temperature variations impact ring sizes, ensuring better accuracy in sizing. ↩