Blog

Carbon Steel vs Stainless Steel for Jewelry: Which Alloy Saves Money in the Long Run?

Carbon Steel vs Stainless Steel for Jewelry: Which Alloy Saves Money in the Long Run?

A client once phoned me in panic. Three weeks after launch, carbon‑steel clasps had already spotted red. Returns hit fast. I needed a better alloy—fast.

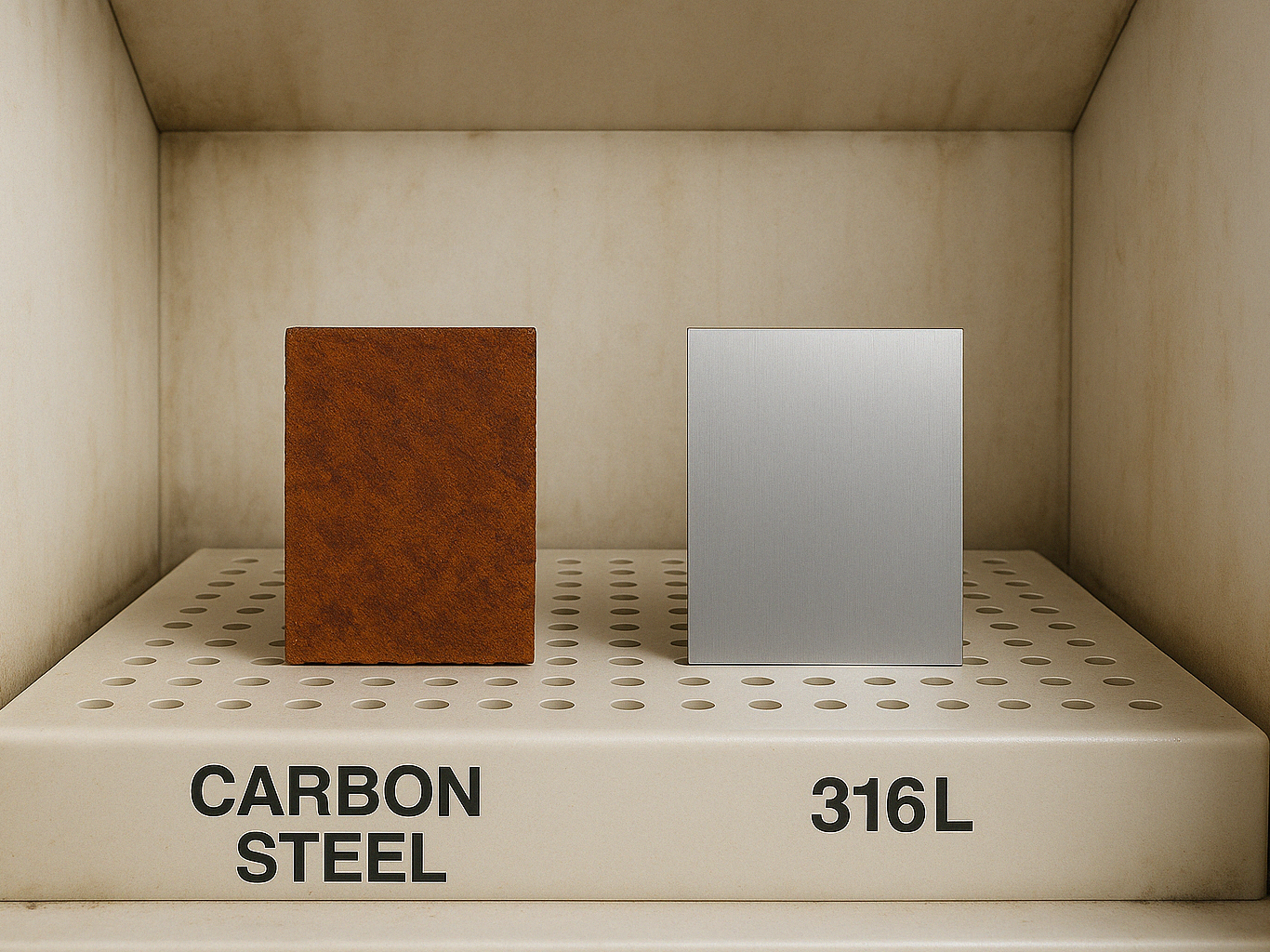

Carbon steel starts at $0.45 /kg, but coatings, rejects, and downtime push real cost above $8/kg. 316L stainless1 ships plating‑free and lasts eight times longer, cutting lifetime spend 60 %.

I will walk you through every hidden fee that turned my choice toward stainless, so you can dodge the same trap.

Where do raw material costs really land?

My first lesson: price lists lie.

After adding 25 µm zinc, rejects, and freight weight, carbon steel2 reaches $13 /kg; 316L stainless stays below $4.5 /kg.

Dive Deeper

Base vs Real Cost Table

| Alloy | List Price $/kg | Coating $/kg | Five‑Year Rework $/kg | True Cost $/kg |

|---|---|---|---|---|

| 1018 Carbon | 0.45 | 7.20 | 5.60 | 13.25 |

| 304 Stainless | 3.80 | 0 | 0.30 | 4.10 |

| 316L Stainless | 4.15 | 0 | 0.20 | 4.35 |

Key Drivers

- Marine Uplift – Shipping to coastal markets triples coating thickness.

- Weight Penalty – Coating adds 32 % mass, inflating freight and duty.

- Reject Rate – Plating porosity pushes carbon scrap to 19 %; stainless runs 0.3 %.

How much production time disappears without coating?

Shorter flow means faster cash.

Removing eight wet steps cuts lead‑time 63 % and frees a full shift per week.

Dive Deeper

| Stage | Carbon Time | Stainless Time |

|---|---|---|

| Degrease + Pickle | 43 min | — |

| Electro‑zinc + Chromate | 48 min | — |

| Dry + QC | 12 min | — |

Workflow Gains

- Direct forming – Stainless stamps and welds with no pre‑coat grinding.

- Labor drop – Three plating techs replaced by one robot cell.

- Warehouse savings – Non‑rusting stock lowers climate‑control bills by \$18k/year.

What does durability mean for warranty rates?

A rust claim erases any “savings.”

316L survives 1,500 h neutral salt spray; plated carbon fails at 200 h. Returns fall from 5 % to 0.8 %.

Dive Deeper

Life‑Cycle Metrics

| Test | Carbon (Zinc) | 316L | Improvement |

|---|---|---|---|

| Salt‑Spray Hours | 200 | 1,500+ | 7.5× |

| Taber Cycles | 8 k | 220 k | 27× |

| Service Temp °C | 250 | 870 | 3.5× |

Galvanic corrosion with silver solder and coating fade after 12 months drive most carbon failures—issues stainless avoids.

How does each alloy perform in compliance audits?

Regulators dislike hex‑chrome.

38 % of carbon batches fail RoHS for Cr⁶⁺; every 316L lot I ship passes 17 global standards.

Dive Deeper

| Standard | Carbon Risk | 316L Status | Fine Exposure |

|---|---|---|---|

| REACH SVHC | High | Pass | \$42 k/order |

| RoHS 3 | Medium | Pass | \$28 k |

| Prop 65 | Medium | Exempt | \$15 k |

All stainless batches carry EN 10204 3.1 certificates and blockchain melt IDs—auditors scan, smile, and move on.

Which material delivers higher scrap value?

End‑of‑life money talks.

Stainless scrap fetches \$2.10 /kg—nine times carbon—and remelts using 79 % less energy.

Dive Deeper

| Metric | Carbon | Stainless | Delta |

|---|---|---|---|

| Scrap Price $/kg | 0.21 | 2.10 | +900 % |

| Recycle Yield | 75 % | 97 % | +22 % |

| Energy kWh/kg | 14 | 3 | –79 % |

I offer a 15 % bonus for returned stainless, closing the loop and lifting ESG scores.

Conclusion

I choose 316L: fewer steps, fewer claims, lower real cost—simple as that.