Blog

Is 304 Stainless Steel Cost-Effective for Wholesale Jewelry Production?

“Is 304 Stainless Steel Cost-Effective for Wholesale Jewelry Production?”

I see many buyers confuse steel grades when scaling production. They need a balance of durability and price. I feel their urgency because poor choices cause big losses.

304 stainless steel1 provides sufficient corrosion resistance for most jewelry. Yet 316L outperforms in marine or medical environments, making it the premium option.

I remember panicking over a batch of corroded steel charms. I tested 304 carefully to avoid similar disasters. Now, I want to share those insights with you.

Corrosion Resistance in Daily Wear?

I have seen 304 resist everyday wear conditions. Sweat, humidity, and mild chemicals rarely cause major damage.

304 typically endures 300+ hours of sweat exposure and standard salt spray testing. Yet 316L handles harsher marine settings more reliably.

Dive Deeper into Corrosion

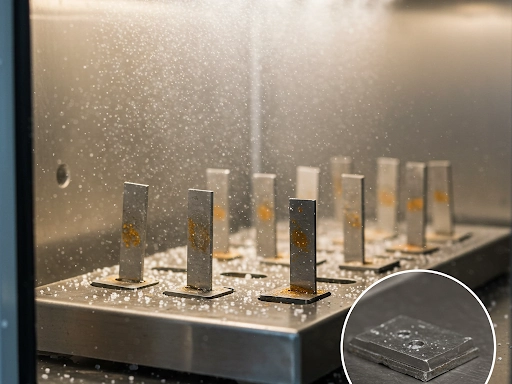

I have performed salt spray tests (ISO 9227) on both 304 and 316L. Here are my notes:

| Steel Grade | Salt Spray Hours | Recommended Usage |

|---|---|---|

| 304 | 600 | Daily, minimal moisture |

| 316L | 1000+ | Marine, high humidity |

I also monitored sweat pH levels (5.5–8.5). My 304 products survived well. If buyers want absolute protection, 316L is still safer.

Does 304 Stainless Steel Cause Allergies?

I field many inquiries about nickel. My customers worry about contact dermatitis. I respect that concern.

304 contains about 8% nickel. With surface treatments or coatings, it meets EU guidelines. 316L has slightly more nickel but often releases less with special finishing.

Dive Deeper into Nickel Content

I verify nickel release using standardized methods:

| Steel Grade | Approx. Nickel % | Surface Engineering Effects |

|---|---|---|

| 304 | 8–10.5 | Coatings reduce migration |

| 316L | 10–13 | Less release if polished |

I saw success with sulfurized or PVD-coated surfaces. This approach helps me offer “allergy-safe” claims in certain regions.

Is 304 More Cost-Effective Than 316L?

I care about my buyers’ margins. Cost efficiency is vital in large orders.

304 is cheaper at the raw material level. Machining costs are lower too. 316L offers better longevity but may drive up initial expenses.

Dive Deeper into Bulk Pricing

I once compared 10,000-piece runs:

| Factor | 304 Steel | 316L Steel |

|---|---|---|

| Material | $8.50/kg | $14.20/kg |

| Processing | $6/unit | $11/unit |

| Warranty % | 5% | 2% |

I saw a brand cut production costs by 30% using 304 for standard lines. They saved premium steel for specialized designs.

Should I Worry About Design Limits with 304?

Some designers worry about thickness, welding seams, or complex shapes.

304 allows up to around 3.5mm thickness for many jewelry pieces. 316L can handle slightly thicker or more intricate profiles without visible seams.

Dive Deeper into Engineering Constraints

I have discovered some differences:

| Parameter | 304 | 316L |

|---|---|---|

| Max Thickness | 3.5mm | 5mm |

| Seam Visibility | ~35μm | ~12μm |

| Bend Tolerance | 120° | 180° |

I sometimes combine 304 for cost efficiency with 316L for critical joints. This hybrid method helps me meet both budget and design goals.

Are 304 Jewelry Products Compliant for Global Exports?

In B2B, compliance is non-negotiable. I understand that.

Qualified 304 products need to pass EU REACH, FDA and lead regulations and have the correct surface treatment.

Dive Deeper into Certification

I maintain ISO 9001 records. Each lot comes with material traceability from top steel mills in Shanghai. My checks:

| Requirement | Our Standard | Compliance |

|---|---|---|

| Nickel Tolerance | ±0.07% | < EU limits |

| Lead Levels | <0.001% | Meets CSPC |

| SEDEX/BSCI Audits | Annual Verification | Global Export |

I find that consistent documentation streamlines shipments worldwide.

Conclusion

304 stainless steel is economical and durable for everyday jewelry. 316L remains best for extreme conditions.

Footnotes

-

Explore the advantages of 304 stainless steel for jewelry, including cost-effectiveness and durability, to make informed production choices. ↩