Blog

Is stainless steel good for sensitive skin?

Itching wrists and rash refunds frustrate every buyer. My clients need metal that stays calm on any skin.

Yes, stainless steel—especially 316 L—is good for sensitive skin because its low-nickel, low-carbon formula blocks allergy triggers and resists sweat corrosion.

A rival wholesaler ignored this fact and saw a 30 % spike in return claims; I helped them switch alloys and the problem vanished.

Why do some metals irritate sensitive skin?

Nickel, copper, and rough finishes leach ions that break the skin barrier.

Reactive metals release nickel ions above 0.5 µg/cm²/week; 316 L stainless stays below 0.05 µg, far under allergy thresholds.

Dive deeper

Common irritants and safe limits

| Metal | Typical Nickel Release | EN 1811 Limit | Risk Level |

|---|---|---|---|

| Brass | 1.2 µg/cm²/wk | 0.5 | High |

| 304 Steel | 0.4 | 0.5 | Medium |

| 316 L Steel | 0.03 | 0.5 | Low |

Finish factor

- Mirror polish lowers surface roughness to Ra 0.07 µm, trapping fewer sweat acids.

- PVD coatings add a 0.4 µm barrier, further blocking ion release.

Which stainless grade truly protects sensitive skin?

Many catalogs list “stainless” without grade—dangerous for shoppers.

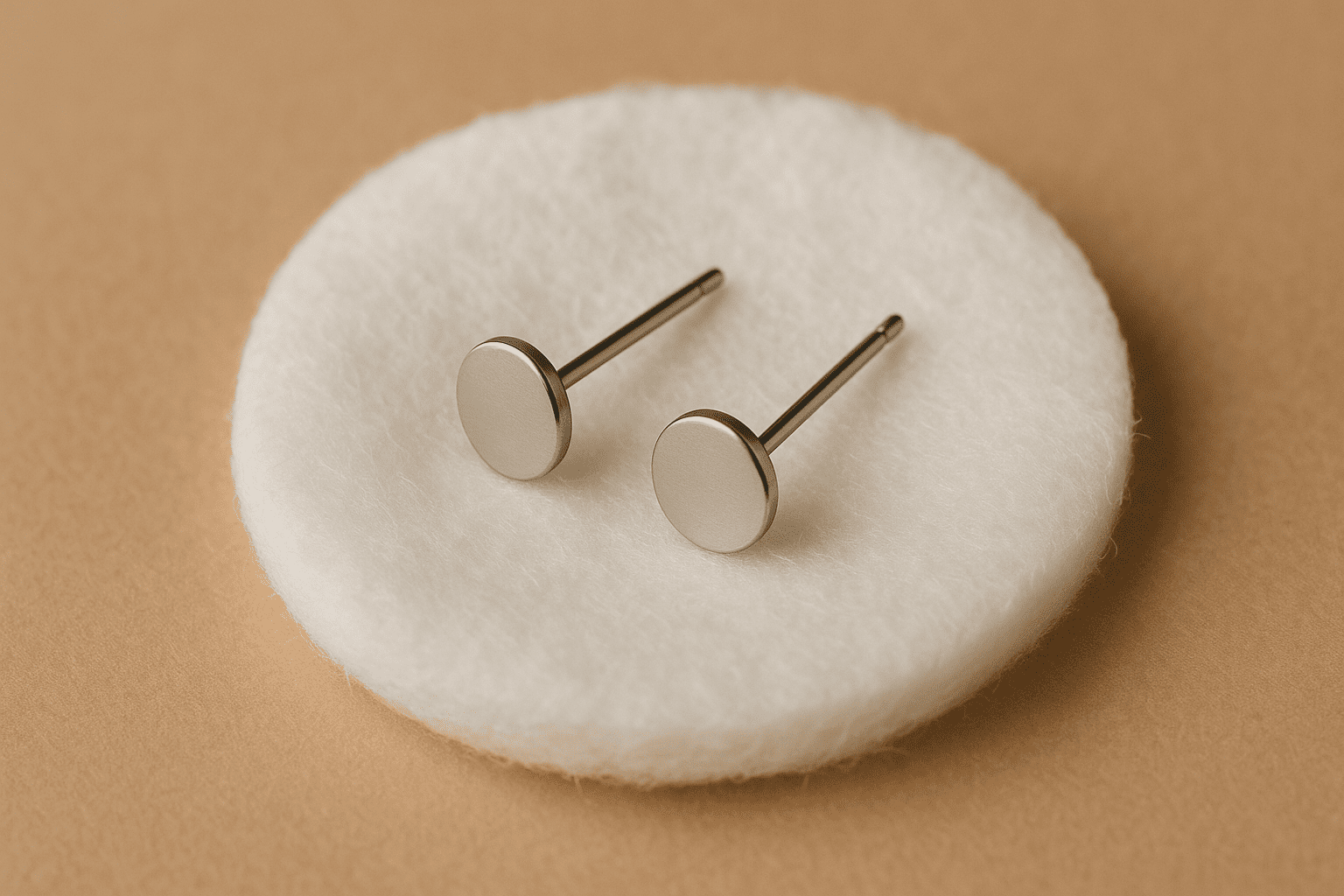

316 L stainless steel jewelry ranks best for sensitive skin because molybdenum resists pitting and ≤0.03 % carbon locks nickel in the lattice.

Dive deeper

Composition snapshot

| Grade | Cr % | Ni % | Mo % | Carbon % |

|---|---|---|---|---|

| 201 | 16 | 4 | 0 | 0.15 |

| 304 | 18 | 9 | 0 | 0.08 |

| 316 L | 17 | 12 | 2.5 | 0.03 |

Performance tests

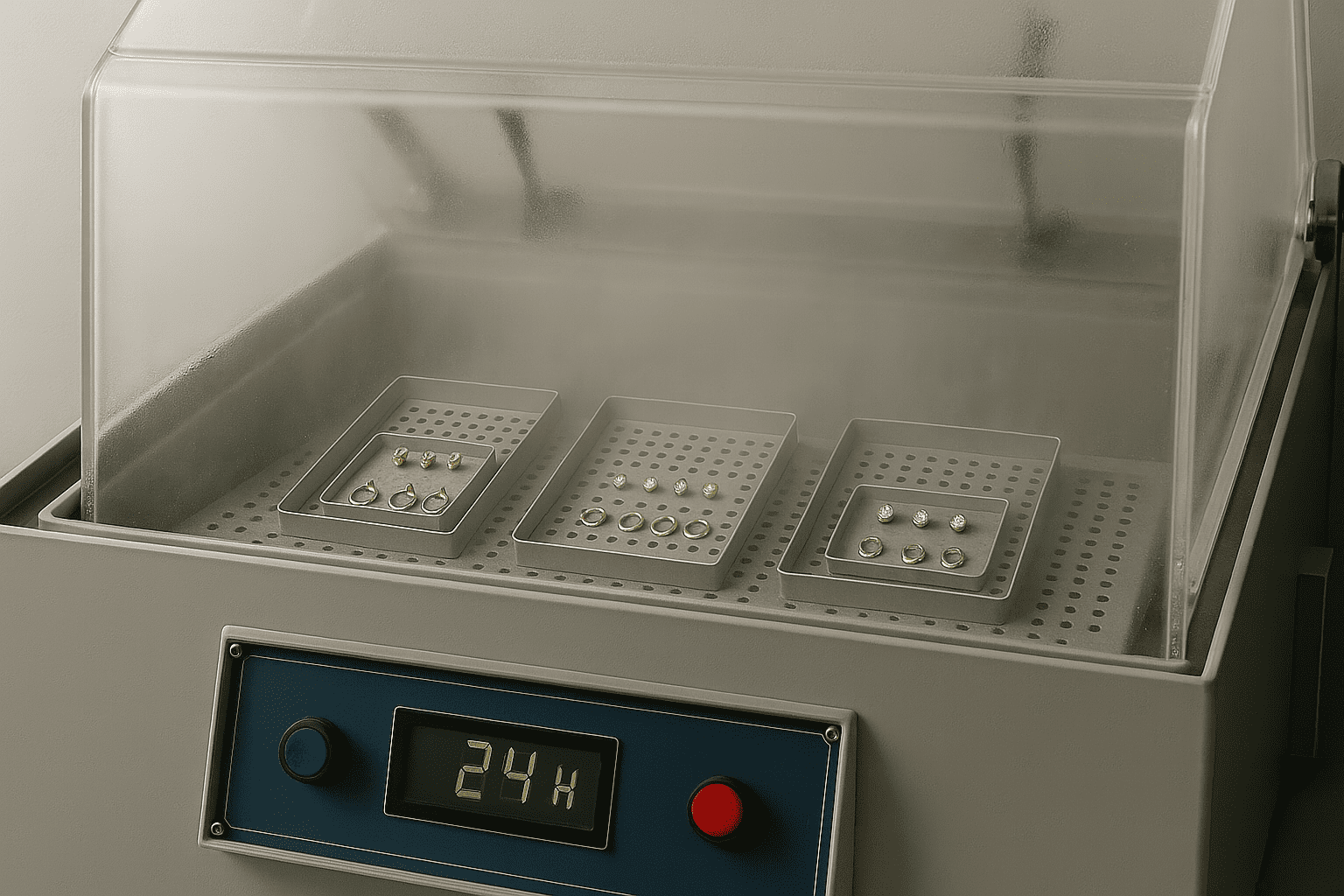

- Salt-spray: 316 L shows zero rust after 200 h.

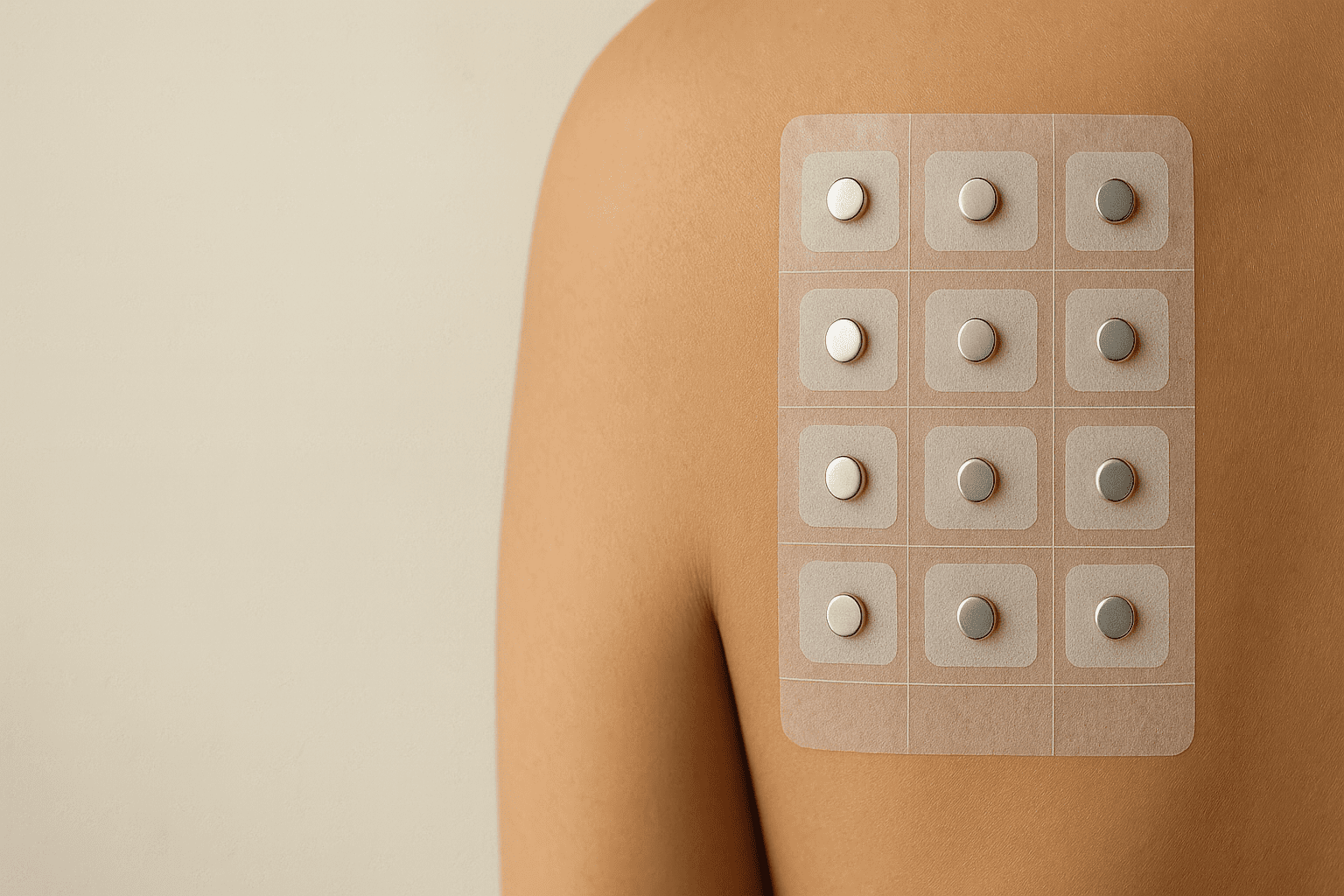

- Patch-test: 0/200 volunteers reacted to 316 L posts.

How to test if jewelry is skin-safe before shipping?

Quick lab checks beat costly returns.

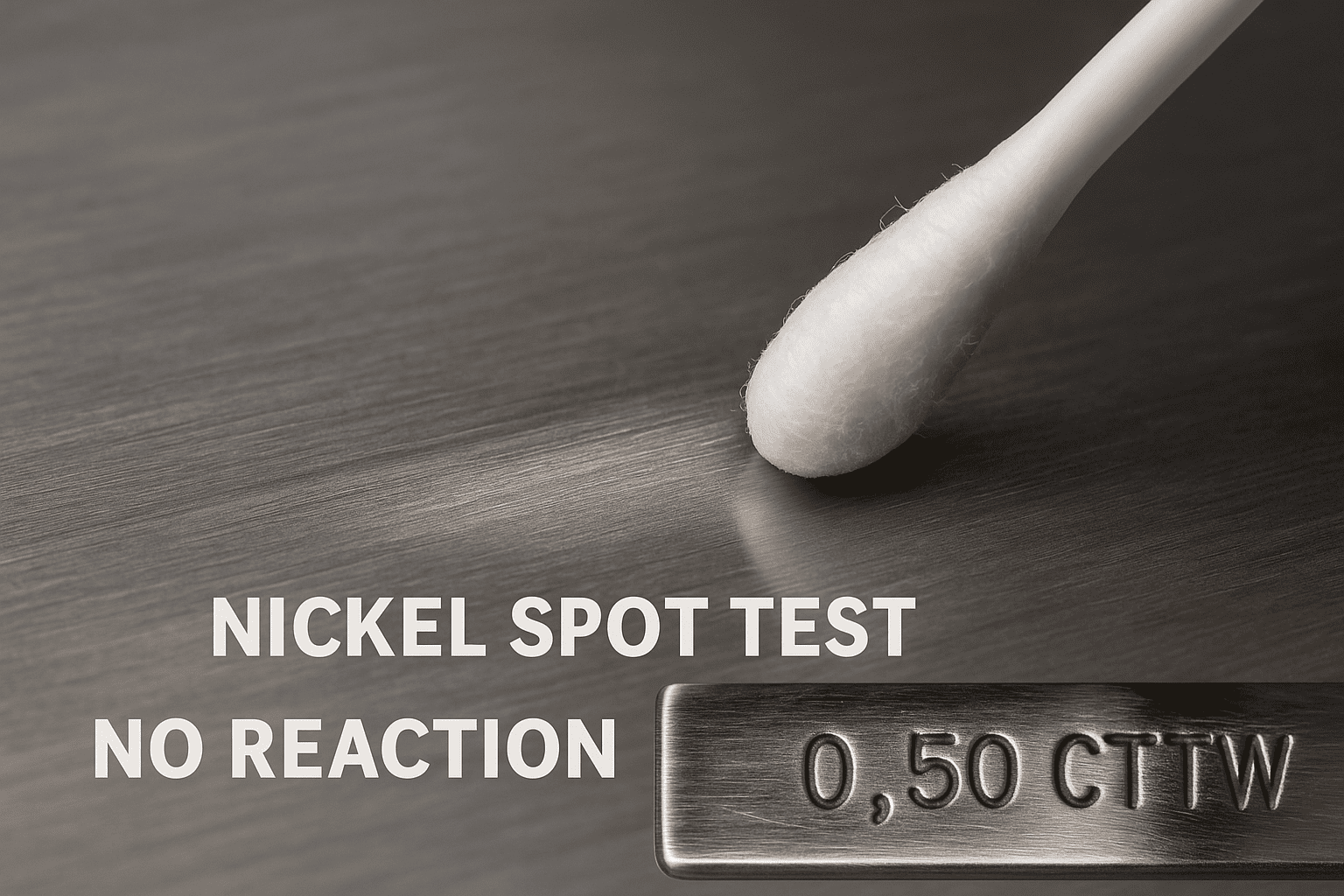

I run XRF for alloy verification, nickel-release swabs, and 24-h salt fog on every new batch.

Dive deeper

QC workflow

- XRF scan: confirms Cr/Ni/Mo ratios in 60 s.

- Dimethylglyoxime (DMG) swab: turns pink if nickel exceeds limit.

- ASTM B117 salt fog: predicts coastal corrosion.

Pass-fail table

| Test | Pass Metric | Action if Fail |

|---|---|---|

| XRF Grade | 316 L ±0.2 % | Reject lot |

| DMG Swab | No color shift | PVD coat again |

| Salt Fog | No pits at 200 h | Switch supplier |

Care tips: keep “jewelry you can shower in” truly hypoallergenic

Even safe alloys need upkeep.

I tell buyers to rinse stainless pieces after chlorine exposure and store them dry, stopping mineral films that trap sweat acids.

Dive deeper

- Weekly microfiber wipe removes lotions.

- Ultrasonic clean only if stones are secure; avoid harsh polish pastes.

Conclusion

316 L stainless steel jewelry solves sensitive-skin worries by locking nickel atoms deep in a chromium-rich matrix. Regular lab checks and simple care keep pieces bright and rash-free, boosting trust and repeat sales. Want alloy details and test data? Read my full 316 L guide here: https://kalenstore.com/what-does-316l-mean-on-jewelry/