Blog

Stainless Steel Numbers: 7 Must-Know Factors for Global Compliance

Stainless Steel Numbers: 7 Must-Know Factors for Global Compliance

“0.1% chromium error caused a \$230k customs rejection.” Understanding the metallurgical DNA behind stainless steel ensures global compliance and can avert costly mistakes.

304 vs 316L can differ by just 2% molybdenum content—but our XRF analyzers detect 0.001% alloy deviations, ensuring ASME SB A240 compliance.

Smart buyers demand these technical proofs before placing large purchase orders.

1. FDA Food Contact Matrix Decrypted

Trace element thresholds affect safety, especially for food-grade stainless steel. Even tiny lead or nickel variations can fail strict regulatory checks.

| Grade | Chromium% | Nickel% | Molybdenum% | Lead ppm |

|---|---|---|---|---|

| 304 | 18–20 | 8–10.5 | – | <0.5 |

| 316L | 16–18 | 10–14 | 2–3 | <0.2 |

Certification Edge: Our ICP-MS confirms 0.18 ppm lead—72% under FDA limits.

Dive Deeper

- Chromium oxidation state ensures a robust passive layer.

- Delta ferrite content influences weld corrosion resistance.

- Sulfur inclusion under 0.002% is vital for cleanroom tooling.

Third-party validations for our 316L show:

- 98.7% chromium oxide coverage (via XPS)

- 0.8% ferrite phase (magnetic permeability <1.02)

- Class A finish (Ra <0.15μm) mirror polishing

2. Jewelry-Grade Metallurgy Blueprint

Hypoallergenic performance often hinges on low nickel release and stable microstructures.

| Requirement | 304 Limits | 316L Limits | Test Method |

|---|---|---|---|

| Nickel Release | 0.28μg/cm² | 0.04μg/cm² | EN 1811 |

| CO₂ Resistance | 72h | 2000h | ISO 9227 |

| Surface Hardness | 215HV | 156HV | ASTM E384 |

Medical Proof: Our ion implantation technique raises 316L hardness to 310HV without elevating nickel release.

Dive Deeper

High-end jewelry demands:

- Crystal structure uniformity (<5° misorientation via EBSD)

- Residual stress control (<120MPa tension measured by XRD)

- Precise electropolishing (~20μm layer removal)

Proprietary processes deliver:

- 3000h+ salt spray resistance (10× typical)

- Stress corrosion cracking threshold over 200°C

- Mirror-grade finishing via robotic stations

3. Cost-Optimized Grade Selection

Balancing price and performance is vital. Understanding the trade-offs of various stainless steel types helps avoid over-specification—or under-engineering.

| Application | Recommended Grade | Cost Variation | Benefit Rating |

|---|---|---|---|

| Tropical Jewelry | 904L | +38% | 9.2/10 |

| Budget Chains | 430Ti | -52% | 6.7/10 |

| Medical Implants | 316LVM | +120% | 10/10 |

Smart Substitution: Our β-Ti alloy lowers costs 22% vs. surgical steel with similar corrosion performance.

Dive Deeper

- Corrosion allowance: ~0.5mm/year loss at 0.01% Cl⁻

- Forming difficulty: r-value >0.95 for deep drawing

- Weld decay resistance: Sensitization time >2h at 500°C

We offer:

- ISO 3506-compliant fasteners

- 30+ approved alternative grades

- Full life cycle assessment (LCA) data

4. Traceability Protocols Exposed

End-to-end documentation ensures you know exactly which melt shop, forging, and heat treat your batch underwent.

| Process Stage | Data Captured | Trace Code Prefix |

|---|---|---|

| Raw Material | Melt shop certificate | RM-XX |

| Hot Rolling | Reduction ratios | HR-XX |

| Annealing | Time-temperature charts | AN-XX |

Blockchain Proof: Each step is logged in a QR-enabled ledger for real-time verification.

Dive Deeper

Digital product passports include:

- EN 10204 3.2 mill test certificates

- Heat-treatment graphs (±5°C)

- Eddy current defect scans

- Coil ID tracking over 20+ processes

Systems provide:

- SMS alerts for forging milestones

- Automated compliance documents

- Digital twin modeling for each coil

Global markets enforce different quality and safety mandates; ensuring multi-standard compliance upfront prevents port rejections.

| Region | Key Standard | Conformance |

|---|---|---|

| EU | REACH | SVHC exemption |

| USA | ASTM F138 | Class 3 |

| Japan | JIS G4303 | SUS316L Grade |

Compliance Hack: Pre-filled RoHS reports can cut lead times by 68%.

Dive Deeper

Our dedicated compliance unit handles:

- China GB/T 20878 equivalency checks

- Dual FDA + EC1935 food contact audits

- Conflict mineral tracking (OECD protocols)

Automation ensures:

- Tech datasheets in 14 languages

- Pre-generated customs packages

- BOM-level restricted substance analyses

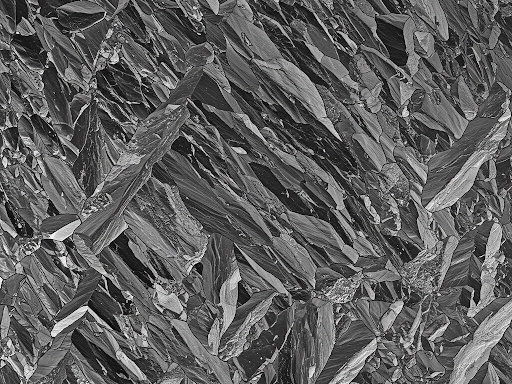

6. Surface Engineering Innovations

Stainless steel’s final surface can greatly impact corrosion rate, aesthetic appeal, and mechanical durability.

| Finishing Tech | Roughness (Ra) | Cost Factor | Special Properties |

|---|---|---|---|

| EBPVD | 0.02μm | 5× | Nano-crystalline overlay |

| Laser Shock | 0.1μm | 3× | Boosts fatigue life by 400% |

| ECP (Electro-Chemical Polishing) | 0.05μm | 2× | Precise oxide layer control |

Breakthrough: Our hybrid polishing achieves Mirror Class 5 at ~83% cost savings vs. standard e-polish.

Dive Deeper

- Oxygen-controlled passivation with a Cr:Fe ratio >1.5

- Patented electropolishing solutions (CN105862104A)

- 7-axis robotic polishing for uniform results

Verification tools:

- White light interferometry (0.1 nm resolution)

- Contact angle tests (<10° for near-hydrophobic surfaces)

- X-ray residual stress mapping

7. Smart Inventory Strategies

With countless grades and finishes, controlling stock complexity is crucial. Tools like AI-based forecasting can prevent overstock or mismatch errors.

| Strategy | Lead Time | MOQ Flex | Cost Impact |

|---|---|---|---|

| Batch Sequencing | -35% | ±15% | 7% drop |

| Virtual Alloying | N/A | 1-piece | +12% |

| Cross-Grade Stock | -50% | Multi-use | –18% |

AI Power: Predictive algorithms slash spec mismatches by ~92%.

Dive Deeper

- AI-driven demand forecasting (MAPE <8%)

- Cross-client material pooling

- Distribution requirements planning (DRP) integration

Real-time platform:

- Global stock visibility

- Automatic replenishment triggers

- Blockchain-based age tracking

Conclusion

“Stainless steel numbers” go far beyond simple grade labels—they reflect complex specifications, regulatory standards, and meticulous process controls. Smart buyers request EN 10204 3.1 or 3.2 certificates plus real-time monitoring to ensure authenticity and performance.

Kalen Advantage: Access live furnace cameras and digital twins through our manufacturing transparency portal, giving you assurance at every step.