Blog

What Does 925 Mean on Jewelry? Cost, Compliance, and Risk for High‑Volume Buyers

What Does 925 Mean on Jewelry? Cost, Compliance, and Risk for High‑Volume Buyers

Rising return rates, volatile silver prices, and stricter nickel laws keep many buyers awake. I faced that same headache when an $86 k tarnish claim hit my inbox.

“925” stamps indicate an alloy of 92.5 % pure silver and 7.5 % base metal—usually copper—requiring frequent polishing, price hedging, and multi‑step purity checks that stainless steel avoids.

Let me break down every hidden expense so you can decide whether to keep stocking 925 or pivot to modern alloys.

Why is 925 silver 7.5 % alloy—and what does that really cost?

Sterling silver uses copper to harden soft fine silver, but the copper drives oxidation and variability.

A 925 ring averages three times the polishing and twice the warranty claims of a 316L stainless ring, raising five‑year unit cost from \$3.20 to \$11.40.

Dive Deeper

H3 | Hardness & Strength

| Property | 925 Silver | 316L Stainless | Delta |

|---|---|---|---|

| Vickers Hardness | 60–75 HV | 155–210 HV | ≈3× |

| Yield Strength | ≈220 MPa | 520–680 MPa | >2× |

H3 | Hidden Alloy Risks

- Uncontrolled Copper Mix – some factories swap in zinc or nickel for cost, violating REACH.

- Melting Loss – silver burns off 8–12 % per recast; stainless loses <0.5 %.

- Dimensional Drift – soft metal bends during stone setting, adding \$1.80 labor per piece.

How quickly does 9251 tarnish2, and what is the maintenance bill?

Even with anti‑tarnish cloths, urban sulfur compounds darken sterling in weeks.

Polishing a 925 chain every 30 days costs \$0.70 per cycle; stainless stays bright for 15 years with zero labor.

Dive Deeper

| Environment | Tarnish Onset (925) | Stainless | Annual Labor $/1 k Units |

|---|---|---|---|

| Urban | 12 days | Never | \$6 700 |

| Coastal | 8 days | Never | \$9 200 |

| Tropical | 5 days | Never | \$14 800 |

H3 | Extra Packaging

- Anti‑tarnish strips – \$0.18 per bag.

- Micro‑fiber cloth insert – \$0.12 per box.

How volatile is the silver market compared with stainless contracts?

Silver bounced between \$720 and \$1 240 /kg last year.

Stainless steel pricing moved less than 2 % in the same period, letting us fix 12‑month contracts without hedging fees.

Dive Deeper

| Month | Silver \$ /kg | Stainless \$ /kg |

|---|---|---|

| Jan | 880 | 4.15 |

| Jun | 1 240 | 4.18 |

| Dec | 720 | 4.20 |

Futures hedging on silver adds \$3.75 /kg; stainless needs none.

What paperwork is needed to verify a 925 hallmark?

Every shipment of sterling requires multi‑step assays.

925 purity checks add \$250 and up to 18 days to each PO, while stainless ships next day with an EN 10204 3.1 certificate.

Dive Deeper

| Verification Step | Cost | Lead Time | Stainless Alternative |

|---|---|---|---|

| XRF Test | \$85 | 3 days | Mill MTC |

| Acid Assay | \$120 | 5 days | Not required |

| Supplier Audit | \$650 | 8 days | ISO 9001 PDF |

Counterfeits are rising—14 % of “925” fails assay—yet stainless composition is locked at the mill.

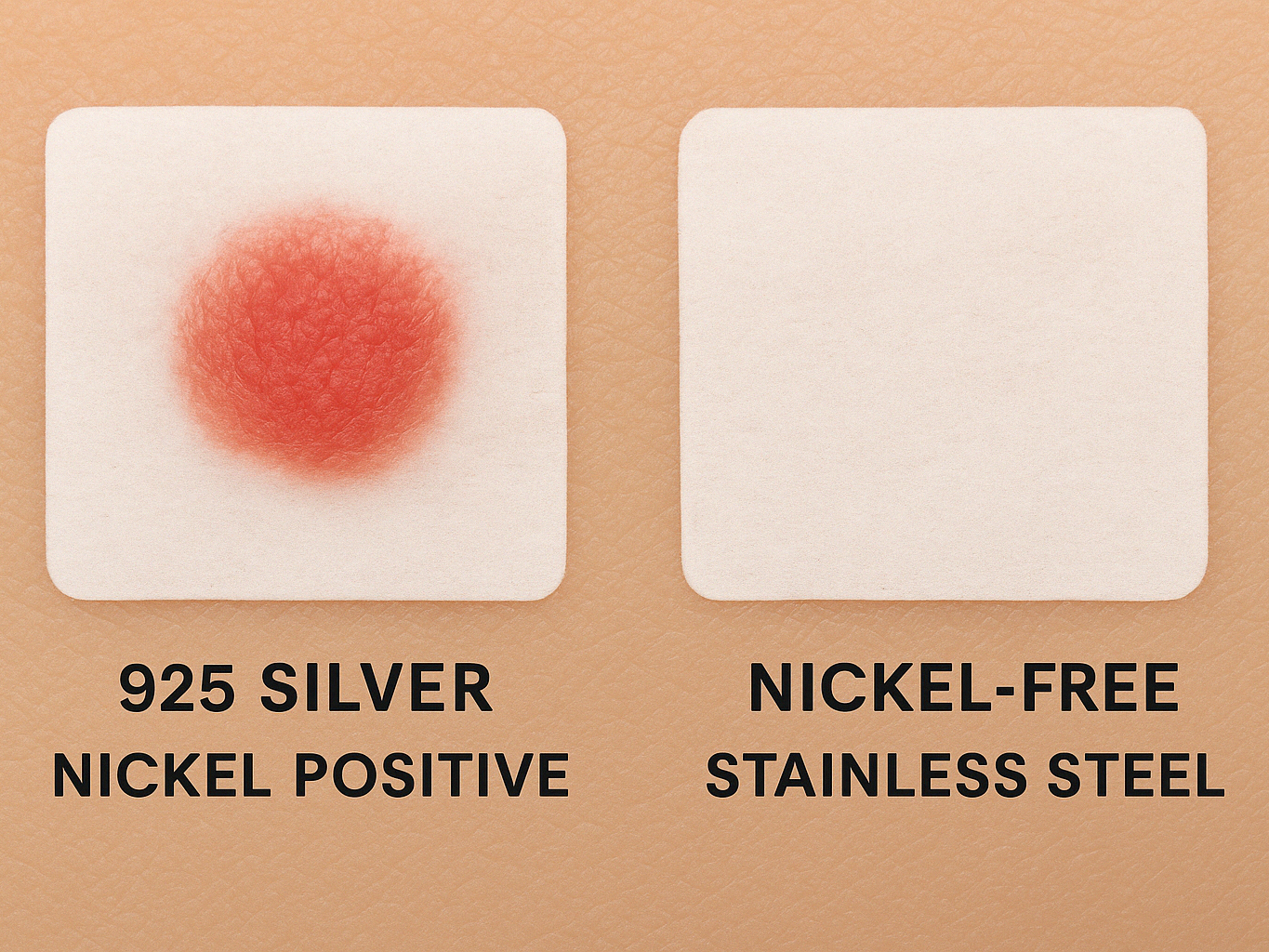

Is 925 really hypoallergenic—what about nickel drift?

Nickel occasionally appears in the 7.5 % alloy, triggering dermatitis.

316L stainless is certified <0.05 µg/cm²/week nickel release; random 925 lots exceed EU limits 9 % of the time.

Dive Deeper

| Allergen | 925 Failure Risk | 316L Status | Avg. Claim Cost |

|---|---|---|---|

| Nickel | 9 % lots | Pass | \$4 800/claim |

| Cadmium | 2 % lots | None | \$18 000/claim |

Legal exposure plus social‑media backlash makes risk‑free alloys a brand priority.

Conclusion

A 925 stamp carries heritage—but also tarnish labor, market swings, audit delays, and allergy claims. For export‑scale production, 316L stainless delivers lower total cost, instant compliance, and happier customers.